Click here to download as a PDF

Wallbarn has been given the opportunity to distribute the Transcend range of WPC decking from Trex (distributed through Arbor Forest UK). This is the ultimate commercial grade composite decking board with long term durability.

Error: Contact form not found.

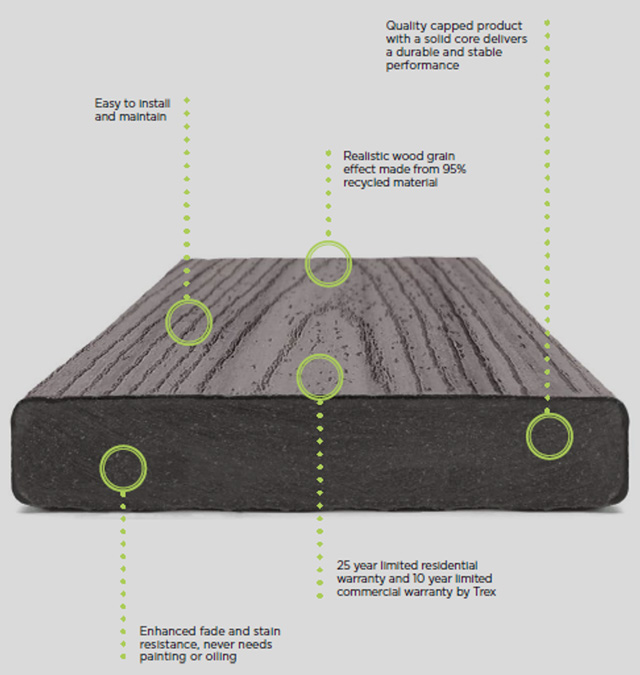

Trex Transcend decking is a solid, dense, stable deckboard with exceptional scratch and stain resistance. It has superior fade resistance and a realistic wood grain effect.

Unlike hollow WPCs, Transcend will not shatter, curl or splinter. It is covered with a super hard polymer shell which is three times the thickness of the industry standard.

It’s solid core is manufactured using a nine element formulation giving it a durable and stable performance. It is covered on three sides with a polymer shell to protect it from scratches and puncturing. This protects the upper and side surfaces completely, but allows the WPC material to breathe.

The boards have a low sheen, natural wood grain appearance and good slip resistance. They are designed to withstand heavy foot traffic in the long-term.

It has enhanced resistance to colour fading and has superior UV resistance. Trex Transcend carries a 10-year performance warranty for commercial applications.

There is a suite of Trex connection compatible fixings and clips to secure the boards to joist bearers along with Wallbarn’s other substructure products.

The side fixings mean there is no surface puncturing of the boards. This makes Transcend suitable for bare feet.

Trex Transcend is a truly recycled product being manufactured from 95% recycled material. This means 95% of every element in the production and packaging process is from recycled sources.

The wood element comes from reclaimed sawdust, meaning no trees are felled for the purpose of making this product. Trex proudly boasts that in its 25 year history of WPC production it has not felled a single tree to make its decking boards. What other manufacturer can say that?

The plastic element within the WPC also comes from a recycled source, and even the plastic packaging is from recycled material.

Trex is a member of U.S. Green Building Council and was the first company in the wood-alternative decking industry to receive an International Code Council Evaluation Service ‘SAVE Verification for Recycled Content’. Trex states clearly that it every year it saves over 360,000 tonnes of wood scrap and plastic film from going to landfill and recycles 1.5 billion plastic bags per annum, through its innovative and industry leading production facilities and techniques.

Trex Transcend has been manufactured in USA since 1996 and has a long track record of superior performance. This brings reliable, more robust logistics and better corporate responsibility.

Much of the WPC and composite decking and cladding materials nowadays is manufactured in China and the Far East. This has brought benefits in terms of pricing but does have downsides:

1. DISTANCE

The sheer distance between UK and the Far East of the globe means extended supply lines.

a. The distance between USA and UK is far shorter, leading to faster transit and less carbon miles and environmental benefits.

b. Interruptions in the logistics can also cause chaos, just consider the Suez blockage in early 2021 when almost all shipping imports either stopped altogether or had to divert around Africa leading to massive delays.

2. LOCKDOWNS

The Covid lockdown restrictions by China and their neighbours has brought severe disruption to the logistics process. Constant opening and closing of key export ports in Asia affects consistency of supply lines.

3. CONSISTENCY & TRUST

The consistency of quality control is vital. How much reliance specifiers, developers and suppliers of decking products expected to carry warranties of 15 years or longer can have on quality control procedures, independent test certificates and QC declarations is often a key question. By working with a company with the track record and reputation of Trex, users can be assured they are working with a partner who can be relied upon.

4. ASSURANCE OF ETHICS & HUMAN RIGHTS

UK and Western companies are duty bound to adhere to extensive human rights legislation including human trafficking, anti-slavery, child labour or other type of worker exploitation or abuse in their supply chains. There are severe civil and criminal penalties for those companies being found not to be

doing so.

Customers also require detailed Supplier Questionnaires where suppliers need to make declarations that they comply to all the relevant laws and regulations, that there is no risk of exploitation of labour and that the supply chain

has been audited.

How certain can senior management of such companies be that their declarations are accurate?

By working with US based Trex, UK buyers can be assured these aspects have been fully audited and they comply absolutely to the regulations.

5. ASSURANCE OF ENVIRONMENTAL PROTECTION

The provenance of raw materials can be questionable in extended and fragmented supply chains in some part of the world.

How can UK buyers be assured that the plastic elements are produced in a proper manner, that the wood fibre is responsibly sourced and that there are no contaminants? How robust are the claims that the materials delivered match the technical claims?

All wood fibre used in Trex decking and cladding materials is waste sawdust from wood processing industry and they state clearly and unequivocally that no trees are felled in the manufacture of their decking boards.

Furthermore there is a clear supply chain trail of all plastic elements used in their decking boards so again, UK buyers can rely completely on the credence of the independent certification and compliance documentation from Trex.

A solid substructure is essential for long-term, high performance installations There are a number of ways to fix Trex Transcend WPC decking boards which are detailed below.

If you would like to receive a free sample pack, please click here.

Accessible, reliable and easy to work with.

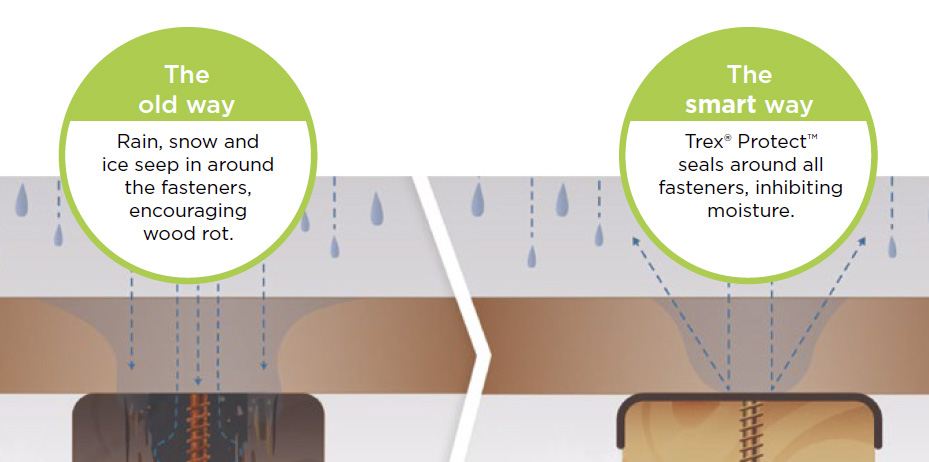

Trex Protect Joist and Beam tape is a self-adhesive butyl tape designed to protect the top of your timber joist or beam. This prevents moisture ingress that can lead to joist rot and loosening of the deck screws and fasteners.

A sub-frame solution that’s accessible,

reliable and easy to work with.

The ArborJoist recycled plastic sub-frame system is the ideal decking sub-frame. It provides a fit-for-purpose foundation that will last for many years, giving peace of mind that the Trex deck will continue to look good and be maintenance free.

handling and installation

Flexibility for every project

The Trex® range of fixing accessories has been selected to provide flexibility for each and every

project, with a choice of fixings to suit a range of different uses and applications. They are designed

to match the superior performance of Trex® decking and to ensure an easy installation whether you decide on a traditional face fix or a screwless finish.

Think sleek, contemporary aluminium deck rails that blend perfectly into your surroundings. Trex Signature® Railing combines effortless style with exceptional strength.