Substructure

Class A Substructure System

Substructure system using MetalPad Ex Pedestals

Key Advantages

- Class A 1 rated (EN 13501-1:2018), fully compliant with BS 8579

- Full metal substructure, zero plastic and zero rubber “gaskets”

- Fast, easy, seamless connection

- Greater spans between pedestals possible

- All fixings and connectors provided

- Spreader plate available for larger weight distribution

Error: Contact form not found.

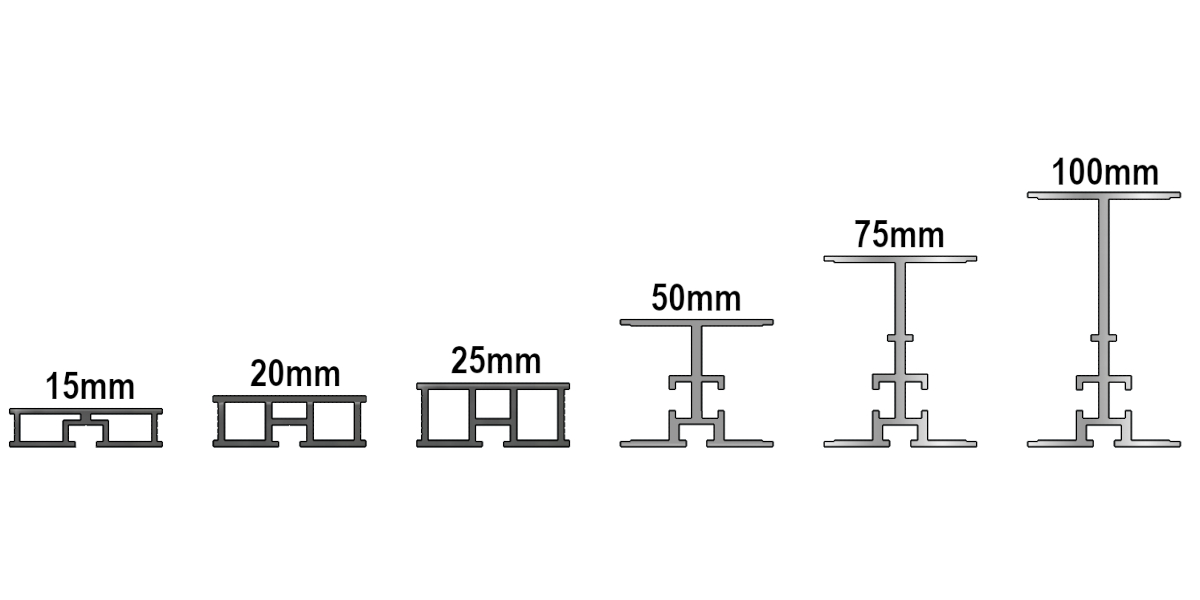

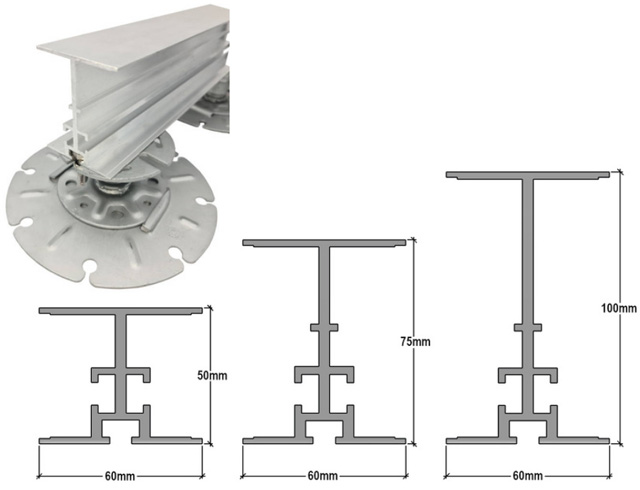

Rail deflection - maximum span between pedestals

| Rail height | Maximum distance between pedestals | Recommended maximum distance |

|---|---|---|

| 15mm | 600mm | 500mm |

| 20mm | 800mm | 625mm |

| 25mm | 1000mm | 625mm |

| 50mm | 600mm | 600mm |

| 75mm | 1200mm | 1200mm |

| 100mm | 2200mm | 1800mm |

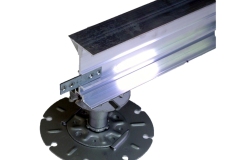

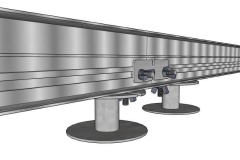

Our Class A substructure system embodies the principle of form following function, merging visual appeal with practicality. This complete system has been designed from scratch by Wallbarn. This solution not only adheres to the rigorous fire safety rules but also creates a high-performance platform for paving and decking projects.

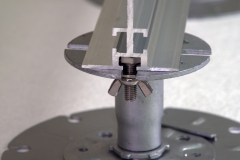

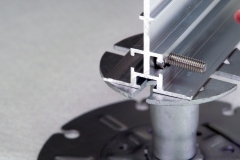

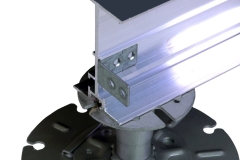

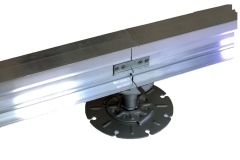

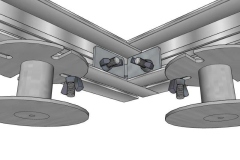

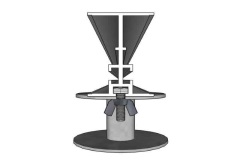

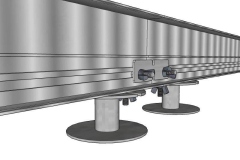

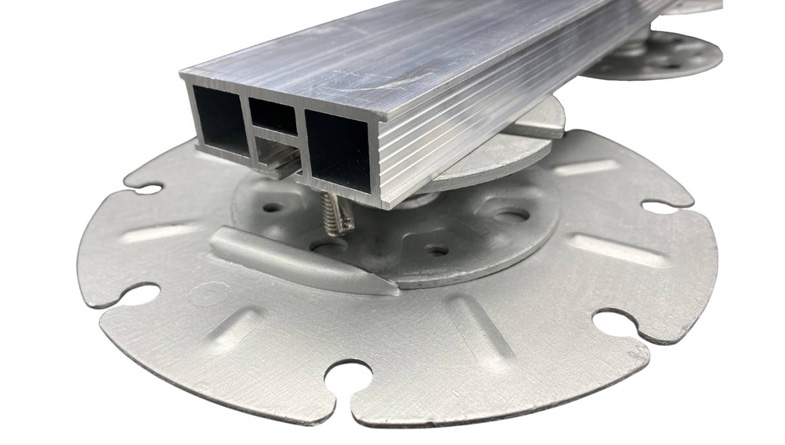

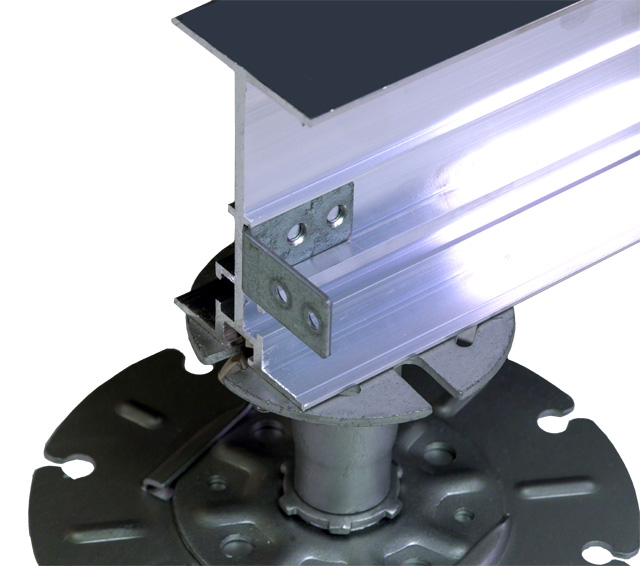

All components have been specifically designed to integrate seamlessly. The aluminium rails/joists fit to the fire-rated MetalPad Ex adjustable pedestal via wing nut fixings. The system is highly versatile, and the substructure can be built to as low as 41mm. Or, using rail-to-rail headpieces will enable a framework of multiple support beams to be built to very large height thresholds, whilst still maintaining durability and stability.

A number of bespoke Class A accessories have been created to help accommodate whatever scenario may arise, particularly on refurbishment and retrofit projects.

Paving / Tiling Applications

- The entire system has been designed, developed & manufactured by Wallbarn to ensure it meets the latest rules regarding Class A systems in the United Kingdom

- Paving headpiece can be fitted anywhere along the rail for perfect alignment of tiles

- All Wallbarn aluminium rails/joists are compatible with Metalpad EX pedestals

- The system is designed to enhance support for slabs and tiles while providing added lateral strength across the deck, ensuring a more stable and durable surface. Official test report

- The system enables faster installation of suspended paving projects, offering millimetre-precise adjustments for a perfectly aligned finish

- Weight bearing joists mean very large spans between pedestals possible

- Very large height thresholds achievable, using Rail to Rail headpiece

- Pave up to walls and parapets with the Metal Edge Plate which provides drainage gap between the wall and perimeter tiles/slabs

- Helps deal with difficult to work with subfloors that are undulating or have features such as vents, plinths or drains

Close

Decking Applications

- Fully integrated substructure system for installing Class A decking.

- All Wallbarn aluminium rails/joists are compatible with MetalPad EX pedestals. Very low height thresholds available with the Wallbarn Joist Holder.

- Our Aluminium joists are made from 3mm thick high grade extruded aluminium, making it strong enough and particularly ideal for high traffic commercial projects.

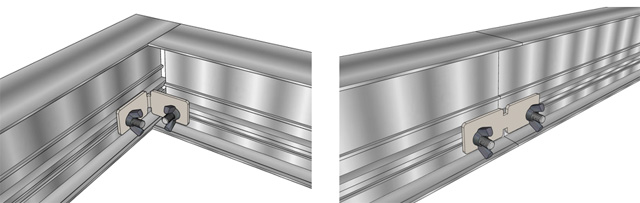

- Class A Decking Clips & Screws available to ensure you fully meet fire safety rules.

- The W Clip 60 for fixing Class A decking boards, is made from black anodised aluminium to ensure it meets Class A standards.

- W Clip 60 comes with it’s own black stainless steel screws as part of a full kit.

- The W Clip 60 has been specifically designed to match the width of our robust aluminium joists to cover the shiny aluminium so they are not seen through the drainage gaps.

- This system streamlines installation, outpacing traditional decking with its specifically designed components. The uniform, broad surface and perfectly level aluminium joists accelerates construction, ensuring a rapid and smooth build.

- Weight bearing joists mean very large spans between pedestals possible.

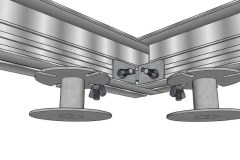

- Joist “ties together” pedestals, fitted together quickly and easily using clips and fixing brackets.

- Massive height range achievable, using Rail to Rail headpiece .

- We have worked hard to create a system that is fast, safe and secure construction of the Class A substructure.

- Fully integrated substructure system for installing Class A1 decking

- Single beam bearer rails mechanically fixed to Metalpad EX pedestals

- Fixings fitted to top of joist

- Designed to give greater support to decking and additional lateral strength across the deck

- Faster installation of suspended decking projects

- Weight bearing joists mean very large spans between pedestals possible

- Joist “ties together” pedestals, fitted together quickly and easily using clips and fixings

- Massive height range achievable, multiple joists can be fixed together

- Fast, safe, secure construction of substructure

Spreader Plate

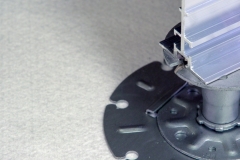

The standard base plate for the MetalPad EX has a 100mm diameter, which is sufficient for applications on hard sub-surfaces like concrete. However, when mounting pedestals directly onto softer surfaces such as insulation or waterproof membranes, an additional Spreader Plate can be used.

By adding the Spreader Plate beneath the MetalPad EX pedestal, the weight tolerance is significantly increased. The pedestal slides into the slots on the top side of the spreader plate and locks into place. The spreader plate itself has a 185mm diameter and has a smooth underside to effectively diffuse and distribute the weight.

Fire Regulations

Our Class A2-s1, d0 rail system meets fire testing standard BS EN ISO 1716:2018

Certified Class A2-s1, d0 (Warrington Fire) – Powder Coating | Steel

They are classified in Class A (‘No contribution to fire’) in

Decision 94/611 /EC

This product has been developed to ensure compliance with:

- Draft BS 8579

- Amendment to Approved Document B May 2020

- Approved Document B 2019

- Advice Note on Balconies in Residential Buildings published by Department of Housing, Communities & Local Government (MHCLG) issued on 24 June 2019

- Regulation 38 of the Fire Safety Building Regulations published by the Government

For further information or to discuss a project, speak to a member of our technical team. Call us on 020 8916 2222 or send us a message here.

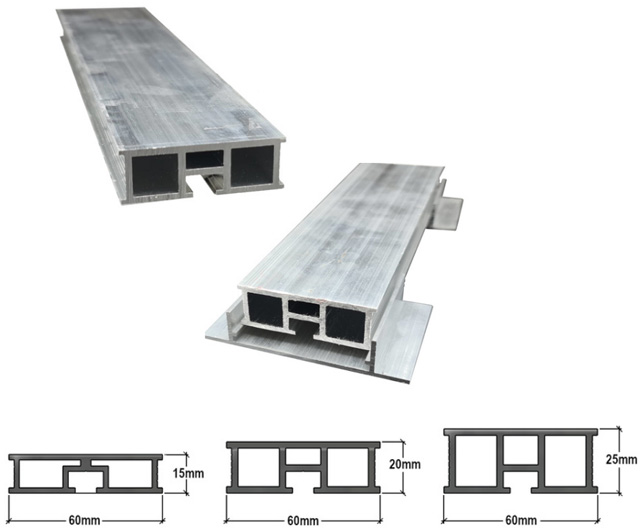

Box Rail

Wallbarn’s Box Rail is made from premium-grade 6063 T6 extruded aluminium. These rails were designed by Wallbarn and manufactured right here in the United Kingdom. They seamlessly cater to both paving and decking applications, creating the perfect Class A non-combustible substructure system.

They are particularly useful for retro-fit projects for the common rip-and-replace schemes currently being undertaken to remove combustible materials from occupied flats. With years of successful implementation on numerous large-scale commercial and residential projects across the UK, the Box Rail has proven its reliability and strength.

Originally conceived as an ultra- low height alternative to timber and composite joist/rails, it has now become a standard choice for Class A decking and raft systems due to its lightweight and easy installation properties.

Key Advantages:

- Designed, developed and manufactured in the UK.

- When used with the Ultra Low Joist Holders, you can achieve a total substructure height threshold as low as 17mm

- Ideal for both decking and paving projects.

- Provides robust support for decking or paving, especially at low height thresholds, and enhances lateral strength across the deck.

- Customised edge profile ensures seamless integration with our other Class A components.

I-Plus Beam

Wallbarn’s I-Plus Beam designed and manufactured here in the UK advances substructure systems with its advanced aluminium rail/joist design.. It excels in retro-fit projects, offering a Class A non-combustible solution suitable for rip-and-replace schemes, ensuring materials meet Class A requirements for safety and compliance.

Available in heights of 50mm, 75mm, and 100mm, the I-Plus Beam adapts to varying height thresholds discovered during the build, allowing for precise adjustments when pairing with MetalPad EX pedestals using the Wallbarn M8 Wing Nut Kit. This creates a fluid, integrated substructure perfect for both decking and paving projects.

Manufactured in the UK, the I-Plus Beam supports end-to-end and perpendicular connections with custom brackets and fixings, detailed on our Connections page. This system not only adds flexibility to your substructure design but also guarantees a durable, reliable, and superior construction solution.

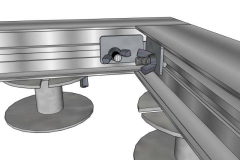

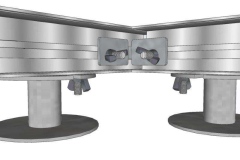

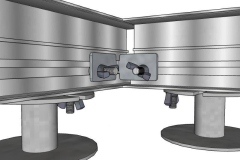

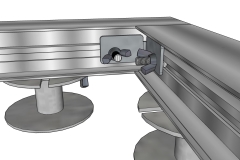

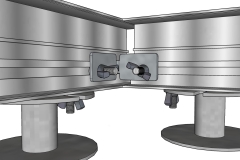

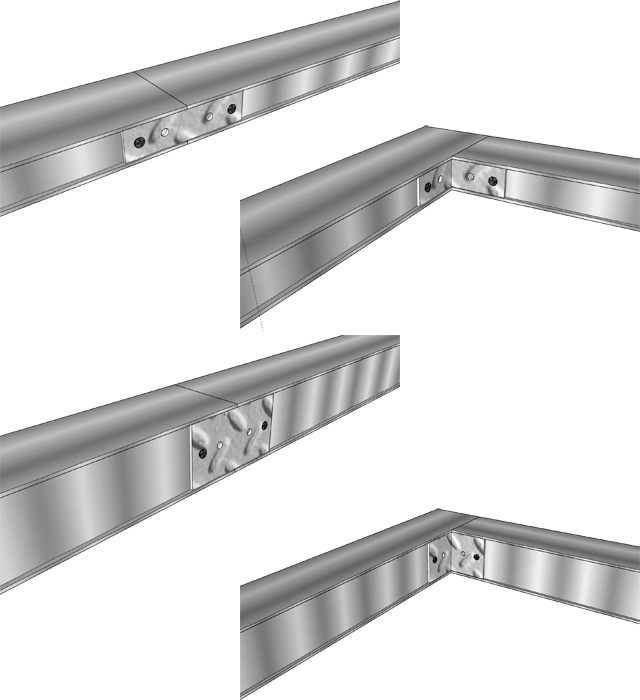

Connections

There are two choices available for connecting I-Plus beams, offering installation convenience. The first approach involves utilizing self-tapping screws for robust mechanical fixing. Both straight and right-angle fixing brackets are equipped with two counter-sunk holes, allowing for easy attachment using the self-tapping screw.

The alternative fixing method involves employing a wing nut and an M8 bolt for manual securing. For this method, the bolt head is inserted into the side or bottom profile of the I-Plus beam, and the wing nut is placed around the bracket manually. This method’s advantage lies in its initial loose framework securing, allowing for flexible realignment to achieve precise positioning. Once the desired alignment is achieved, tightening the wing nuts ensures a secure substructure. This method guarantees a solid and well- aligned construction.

If you have any questions, get in touch.

NBS Source

-

Wallbarn Substructure Class A Fire Rated System for DeckingClose

-

Wallbarn Substructure Class A Fire Rated Paving SystemClose

-

Wallbarn Substructure – Class A System for Paving or DeckingClose

BIM Library

-

Class A Rail Substructure System for Non-Combustible Decking Systems

-

Class A Rail Substructure for Non-combustible Paving Systems