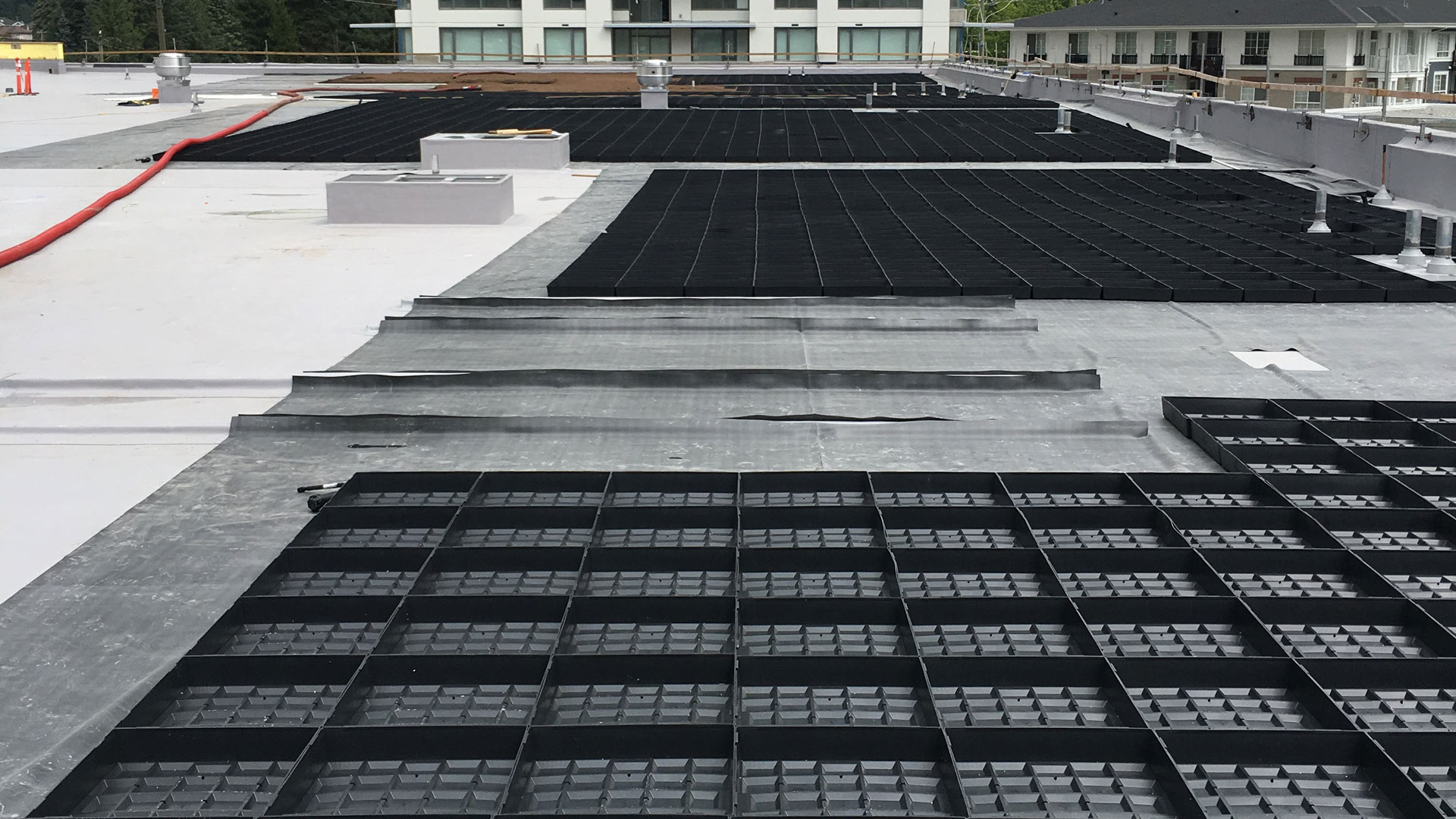

When a major green roof project in South Wales required both outstanding performance and full compliance with fire safety regulations, Wallbarn’s M-Tray® modular green roof system proved to be the ideal solution. Delivered in partnership with Polyroof and Roberts Manufacturing, this installation covered more than 1,200 square metres and is now nominated for multiple roofing and landscaping awards.

Meeting Fire Safety Standards with Confidence

The project was originally specified as a rollout green roof, but the architect raised concerns about fire compliance. Wallbarn was able to confirm that M-Tray® has undergone physical fire testing and is certified to the B Roof(t4) standard—giving complete assurance that the system meets current fire safety regulations.

This compliance, coupled with other practical advantages, prompted a specification change from the original rollout plan to M-Tray®.

Why M-Tray® Was the Right Choice

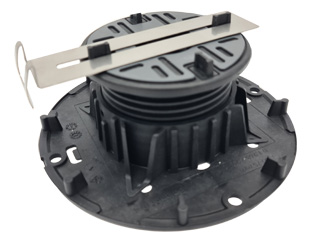

The modular nature of M-Tray® delivers two key benefits that were important for this large-scale build:

-

Futureproofing – Trays can be lifted individually for maintenance without disturbing the rest of the roof.

-

Faster installation – The modular design allows for quicker and more efficient fitting compared to traditional rollout systems.

These features meant that both short-term and long-term performance needs could be met without compromise.

Overcoming the Challenges of a Large Pitched Roof

The scale of the roof and its pitched design required careful planning to avoid long-term issues such as slumping, slippage, or membrane stress at the edges. Wallbarn recommended the installation of horizontal battens and structural parapets to hold the green roof securely in place.

These structural details were fully integrated into Polyroof’s Protec liquid waterproofing system, ensuring that the membrane’s integrity was preserved throughout the project.

Precision Logistics for a Complex Site

Access to the site was another challenge. Located in a busy industrial estate, there were no road closures or dedicated loading bays. With over 5,000 trays required, meticulous logistics planning was essential.

Wallbarn coordinated a four-week delivery schedule, supplying trays in batches of 640 units, three times a week. These were loaded at our farm and delivered in articulated lorry loads to site in a tightly controlled sequence.

Special credit goes to Nia in our Logistics Department, who maintained constant communication with Haran Roofing, Polyroof, and our transport provider to ensure every delivery ran smoothly.

A Successful Outcome – On Time, On Spec, and Award-Nominated

The result is a high-performing, low-maintenance green roof that not only meets fire safety regulations but also demonstrates best practice in design, installation, and project coordination.

The client, along with Polyroof and Haran Roofing, were delighted with the finished roof, which is now up for multiple industry awards—recognition of the planning, technical skill, and collaborative effort that went into its delivery.

To view our case study, please click here.