Looking back on 2025, it is clear that the types of projects Wallbarn has been involved in, and the way our products are being specified, continue to evolve. This year saw a strong mix of large commercial new builds, complex refurbishments, and public sector infrastructure projects, many of which placed increased emphasis on finish aesthetics, fire compliance, durability, ease of maintenance, and long-term performance.

Two of our product categories stood out across these projects. Our M-Tray® modular green roof system and our Class A decking and paving systems were repeatedly selected for demanding environments where quality, aesthetics, compliance and durability were paramount. These projects offered a useful glimpse into where the UK construction industry is heading in these sectors.

The changing landscape of specification in 2025

Across many projects this year, we saw an increased requirement for fire compliant systems. While regulations such as Approved Document B apply to buildings over 11 m, many of the specifiers and design teams we worked with opted for non-combustible systems even at lower levels, down to ground floor.

The reasoning was clear. Designers wanted systems that pre-empt potential future fire safety changes and offered long-term compliance certainty.

This approach delivered confidence over the lifespan of the building and was also shown to support marketing and sales of residential and commercial space. It reduced both health and safety risk and wider commercial risk.

Furthermore, feedback on these finishes consistently showed that these systems met, and in many cases exceeded, market expectations and end client requirements.

At the same time, green roofs continued to gain traction and are now seen as a key component of factors such as Biodiversity Net Gain, Urban Greening Factor, SuDS and BREEAM.

They are increasingly valued as a functional and visual part of the building envelope, helping to reduce the urban heat island effect, create green corridors for wildlife, support pollinators such as bees and birds, improve thermal performance and insulation, and deliver a softer, more attractive roofscape that enhances the overall appearance of the building and its surroundings.

Wallbarn M-Tray® modular green roofs in 2025

M-Tray® was originally developed to make green roofing accessible. The aim was to provide an instant, all-in-one green roof module that could be installed by homeowners, contractors and residential builders without specialist equipment or skills.

Each tray contains substrate, drainage and pre-grown vegetation. Installation requires only a protective fleece over the waterproofing, followed by placement of the trays into position. The simplicity of the system led to widespread adoption in the residential market.

What has become increasingly clear in recent years, and particularly throughout 2025, is how effectively this modular approach translates into large commercial projects and public realm infrastructure.

Growing demand on large commercial schemes

During 2025, Wallbarn M-Tray® was specified on a number of sizeable commercial and public sector projects, with installation scheduled for Q1 2026. These schemes include education and power generation infrastructure. Several exceeded 1,000 sqm, and M-Tray® proved well suited to these projects due to common challenges such as tight security, restricted site access, limited time windows, and areas of high foot traffic.

Interestingly, a key driver for specification, even on very large roof areas, has been future-proofing. M-Tray® allows sections of the roof to be lifted for inspection or maintenance and reinstated without disturbing the wider system. This has become a significant advantage over traditional roll-out green roof systems on large roofs.

The increased uptake of M-Tray® on commercial projects reflects a broader shift in perception. Modular green roofs are no longer seen as a compromise solution. Instead, they are recognised as an efficient, cost effective, future-proof and manageable system well suited to large commercial schemes.

A strong example of this flexibility in action can be seen in the Bee Bus Stop programme. Working with Bauer Media Outdoor UK , following their acquisition of Clear Channel Outdoor , Wallbarn supported the nationwide rollout of Local Authority and City Council operated Bee Bus Stops, jointly designed to integrate directly with the M-Tray® modular green roof system. These installations extend pollinator friendly bee corridors through towns and cities, transforming everyday public infrastructure into biodiverse spaces. From Cornwall to Glasgow and from Belfast to Brighton, with schemes now present in around 60 towns and cities, metropolitan areas across the UK are being gradually greened, demonstrating how M-Tray® can be adapted for public sector projects at scale while delivering real environmental and visual impact.

Why M-Tray® works at scale

Large commercial projects often face challenges beyond the roof build-up itself. Many schemes delivered in 2025 had restricted access, limited space, or tight delivery windows.

M-Tray® modules are supplied on standard Euro pallets, typically carrying 32 trays. These pallets can be moved by pallet truck, forklift, telehandler or crane directly onto the roof. Individual trays can be carried by a single person, making installation possible even where mechanical lifting is limited or unavailable.

On restrictive refurbishment projects, trays have been transported via goods lifts or moved internally using pallet trucks. In some cases, they were carried through stairwells where external access was not possible.

Installation can also be phased. Teams can install hundreds of square metres per day when conditions allow, or work in stages to suit programme constraints and weather.

M-Tray® takeaways from 2025

We have always known M-Tray® to be a strong residential product. The projects specified and delivered in 2025 demonstrated just how well it performs on large commercial schemes.

The scale of installation, variety of access conditions, and demands of long-term management reinforced its suitability for large roofs. Uptake continues to grow as designers look for green roof systems that offer speed, efficiency and minimal disruption.

Class A decking and paving systems

Fire performance and Class A paving and decking systems were at the forefront of the UK construction industry throughout 2025. Our systems were designed and developed to ensure that every component meets Class A specification, without compromise.

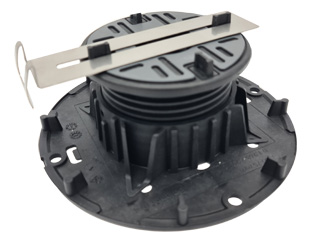

From the outset, the focus was on material selection, connectivity and system integrity. Aluminium rails and joists were chosen for their strength, durability and non-combustible performance. All metal components were specified for high load capacity and longevity. For example, the MetalPad Ex adjustable steel pedestal has a weight tolerance exceeding 5 tonne per pedestal.

MetalPad Ex features a Zintec 200 anti-corrosion coating, providing long-term protection in exposed environments. Independent testing verified fire classification, strength, load tolerance and span capability across the system.

Accessories such as the Spreader Plates and hidden fixings for centrally milled boards were also designed to meet Class A performance. No rubber gaskets or materials that could compromise non-combustibility are used.

What large-scale use in 2025 revealed

While we were confident in the system’s design and testing, large-scale use across both new build and refurbishment projects highlighted additional strengths.

Refurbishment schemes in particular demonstrated the system’s adaptability. Many sites had restricted access, limited storage, or tight working areas. Lightweight aluminium components and efficient handling made installation achievable where heavier or more complex systems would have struggled.

Contractors also valued the ease of assembly and flexibility of the system, particularly on projects where time on site was tightly controlled.

Our systems

Our systems are designed with flexibility and connectivity at their core, allowing them to adapt to projects that are unique, constrained, or technically complex. On site, delays are often caused by incorrect measurements, unforeseen challenges, or restrictive access and working times, all of which can quickly drive up costs. A tried and tested system that can be adjusted, fine tuned or reconfigured as conditions change, while maintaining system integrity, helps teams keep programmes moving and avoid costly rework. This adaptability delivers real value on site and provides confidence for architects, specifiers, contractors and clients alike, which is why we are proud to offer solutions that respond to real world conditions and support all key stakeholders throughout the build process.

Looking ahead to 2026

The projects completed in 2025 reflect an industry becoming more considered in its approach to Class A specified systems. Fire safety compliance, recyclability, durability, long-term maintenance, and long-term visual quality all came to the fore during the year.

For Wallbarn, the year reinforced the value of investing in well designed systems that perform across a wide range of project types. As we move into 2026, we expect continued growth in modular green roofing and increased adoption of Class A systems, even beyond regulated height thresholds.

Several new commercial and public sector projects are already underway, with further announcements to follow in the new year. If 2025 has shown anything, it is that practical, hard wearing, compliant and well designed systems, combined with strong aesthetics, are increasingly important in modern construction.

If you are working on a project where compliance, flexibility and long-term performance are critical, our technical team is always happy to support at early design stage. Get in touch with our Technical Team