Substructure

I-Plus Rail

6063 T6 Aluminium

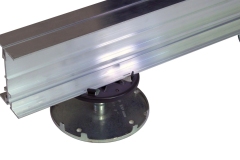

Wallbarn’s premium I-Plus Rails/Joists are made from high grade extruded aluminium. They are a product of Wallbarn’s innovative design and proudly manufactured in the United Kingdom. They are purpose-built for both paving and decking applications and an integral part of our Class A substructure systems. They are compatible with our plastic and fire-rated pedestals.

Key Advantages

- Class A rated (EN 13501-1:2018), fully compliant with BS 8579

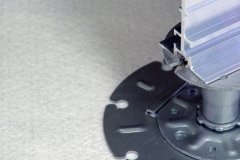

- Extruded profile allows it to simply click onto Wallbarn MiniPad & Mega Balance Pedestal Range.

- Designed to work with MetalPad Ex non combustible pedestals and secured with M8 Wing Nut Kit

- Extruded profile allows it to simply click onto Metalpad & MetalPad EX pedestals

- Due to it’s strength and high quality, they are capable of long spans between pedestals – Official test report

- Will not rust, warp, bend or rot

- Perfectly suited for high height threshold systems commonly used on retrofit projects with steel substructure already in place

Error: Contact form not found.

Rail deflection - maximum span between pedestals

| Rail height | Maximum distance between pedestals | Recommended maximum distance |

|---|---|---|

| 15mm | 600mm | 500mm |

| 20mm | 800mm | 625mm |

| 25mm | 1000mm | 625mm |

| 50mm | 600mm | 600mm |

| 75mm | 1200mm | 1200mm |

| 100mm | 2200mm | 1800mm |

Paving / Tiling Application

- Meets Class A specification: Ideal for use with porcelain tiles and paving slabs for Class A specified projects

- Mechanically fixes to MetalPad Ex pedestals: Makes a secure, non-combustible substructure

- Clips onto MiniPad and Mega Balance Pedestals: Does not require any mechanical fixing

- 60mm wide flat top surface: Provides the ideal platform for supporting tiles or pavers evenly and securely

- Compatible paving headpiece clips onto the rail: Tiles or slabs sit directly on this headpiece, which includes integrated lugs to create drainage gaps; available in plastic or metal options to suit standard or Class A specified projects

- Enhances support: Provides increased lateral strength and prevents movement or rocking of slabs

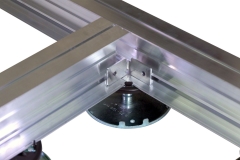

- Quick and easy assembly: I-Plus Rails connect using Wallbarn’s bespoke brackets

- Improves load distribution: Spreads weight more evenly across the surface, helping protect membranes beneath

- High grade extruded aluminium: Suitable for exposed and external environments

Decking Applications

- Fully integrated substructure system: designed for installing Class A fire-rated decking on balconies, terraces, and flat roofs

- I-Plus Beam bearer rails mechanically fix to MetalPad Ex: provides a robust, non-combustible solution

- Compatible with MiniPad & Mega Balance Pedestals without mechanical fixings: rails can slot securely into place for quicker installs in suitable conditions

- 60mm wide flat top surface: provides the perfect platform for securely fixing any decking board type with consistent alignment

- Lightweight aluminium system: easier to handle on- site, reduces risk of manual handling injuries, and simplifies transport to high-level installations

- Speeds up installation: ideal for suspended decking projects requiring minimal fixings and straightforward alignment

- Joists connect seamlessly: uses Wallbarn’s bespoke brackets for a secure and rigid frame beneath the deck

- Stackable design: Multiple I-Plus beams can be layered to meet higher build-up requirements without compromising strength

- Improved airflow and drainage: helps reduce water pooling beneath the deck boards and extends subfloor lifespan

- Compatible with Class A decking boards: supports both fixed and hidden fixing systems

- High grade extruded aluminium: suitable for exposed environments and ensures long-term durability without warping or rusting

Connections

The M8 Wing Nut Kit offers manual securing. Here, the bolt head is inserted into the I-Plus beam’s side or bottom profile, and the wing nut is manually placed around the bracket. This approach’s strength lies in its initial loosely secured framework, enabling flexible realignment for precise positioning. Once the desired alignment is achieved, tightening the wing nuts solidifies the substructure. This method guarantees a robust and precisely aligned construction.

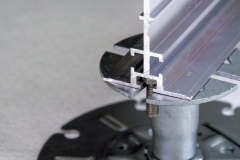

Ballasting & Wind Uplift Issues

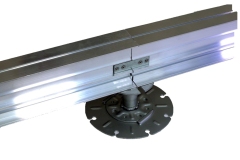

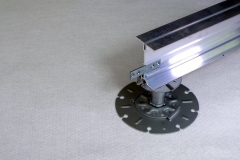

The I-Plus aluminium rail is perfectly suited for adding extra weight to a suspended decking or paving system and can be used as ballast on inverted roofing systems.

This means even inverted waterproofing systems can be sufficiently ballasted without having to penetrate the waterproofing system.

The I-Plus rail has been designed so that a concrete slab/flag can be placed onto the lower ledge of the rail. By placing the next rail into position and pushing tightly to the other side of the slab it locks into position on the lower edges of each I-Plus rail.

This method means even inverted waterproofing systems can be sufficiently ballasted & the decking or paving system does not need to be mechanically fixed to the sub-floor, avoiding the need to penetrate waterproofing layers.

Wind uplift is also an important issue for high rise installations. Although expert professional advice should always be sought beforehand, this method of adding concrete slabs as ballast can help address wind uplift issues. In particular, the non-combustible decking systems can be most suitable for these areas since the boards are mechanically fixed to the rails.

As none of the waterproofing system is penetrated using this ballasting method, there are no issues with manufacturer warranties. This mitigation approach can be particularly effective for high-rise projects and exposed locations.