High-profile rooftop projects leave no room for error. Tight programmes, complex structures and uncompromising quality expectations mean that every stage of installation must be carefully planned and executed. The transformation of Harrods’ former helideck into a luxury rooftop event space was a textbook example of how technical expertise, collaborative working and the right systems on site can make the difference between a challenging build and a successful delivery.

With an immovable deadline ahead of Harrods’ first rooftop event in late May 2025, the installation team needed solutions that were reliable, adaptable and proven in demanding environments.

A Demanding Rooftop Environment

From an installer’s perspective, rooftops always introduce additional complexity. Access constraints, exposure to weather, load considerations and tolerance stacking all require careful management. At Harrods, these challenges were amplified by the nature of the existing structure and the expectations attached to one of the world’s most prestigious retail brands.

The roof featured multiple access points, varying floor heights of up to 400mm and several ramped sections that needed to meet accessibility requirements while remaining visually discreet. At the same time, the finished deck had to integrate seamlessly with a newly constructed internal pavilion, meaning finished levels had to be precise.

Any miscalculation in height, alignment or structural stability would have been immediately apparent and difficult to rectify once installation was underway.

The Importance of a Flexible Substructure

To manage these challenges, TC&D Construction required a substructure system that offered both strength and adaptability. Wallbarn’s I-Plus aluminium rail system provided the foundation for the entire installation, offering consistent tolerances and the flexibility to respond to on-site conditions.

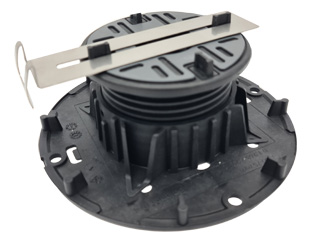

The use of MetalPad Ex pedestals allowed installers to achieve accurate height adjustment across the roof, compensating for uneven substrates while maintaining full Class A fire compliance. This adjustability was critical in managing the significant level changes without resorting to bespoke steelwork or time-consuming site modifications.

For the ramped areas, the aluminium rails were cut to precise angles and cross-fixed to form a rigid framework capable of supporting both the gradient and the expected foot traffic. This level of detailing required confidence in the system’s structural performance and fixing capability.

Solving Alignment Challenges on Site

One of the most technically demanding aspects of the installation was the stacked bond layout specified by the design team. While visually striking, stacked bond patterns are unforgiving. Unlike staggered layouts, they offer no opportunity to disguise inconsistencies or minor deviations.

Achieving perfect alignment across an expansive rooftop required absolute consistency in both the substructure and the decking boards themselves. Wallbarn’s aluminium joists, at 60mm wide, provided a perfectly flat and stable base, eliminating deflection and tolerance variation that can cause cumulative alignment issues.

Equally important was the quality of the Exadeck porcelain boards supplied by Fire Deck. Each board is double-rectified during manufacture, ensuring straight edges and a perfectly flat underside. This prevented rocking, movement or irregular spacing, significantly reducing the need for on-site adjustment and rework.

For installers, this consistency translated into faster progress, fewer corrections and greater confidence as the deck took shape.

Secure Fixing in a High-Traffic Environment

Once the substructure was in place, the Exadeck boards were secured using the Class A W Clip fixing system. This concealed fixing method provides a secure mechanical connection while maintaining the clean, uninterrupted appearance required for a luxury finish.

From an installation standpoint, the fixing system needed to be both robust and efficient. The W Clip system allowed boards to be fixed accurately and consistently, reducing installation time while ensuring long-term stability under heavy use.

Given the intended function of the space as a rooftop event venue, strength and durability were non-negotiable. The complete system was designed to withstand high footfall without movement, noise or degradation.

Programme Management and On-Time Delivery

With Harrods’ first rooftop event scheduled for late May 2025, programme certainty was critical. Delays at any stage could have had knock-on effects for fit-out, commissioning and final handover.

Throughout the project, Fire Deck and Wallbarn worked closely with TC&D Construction, providing technical support, layout advice and responsive delivery coordination. Site visits and ongoing communication ensured that potential issues were identified early and resolved quickly, reducing the risk of delays.

This collaborative approach meant that installation could proceed efficiently, even as complex details were resolved on site. The predictability of the system and the reliability of component supply played a key role in maintaining momentum.

Performance That Installers Can Trust

Beyond installation efficiency, the finished deck needed to perform flawlessly in use. Exadeck’s porcelain surface offers excellent scratch and stain resistance, making it well suited to high-traffic environments where furniture movement, foot traffic and regular events are expected.

The system is also weather-resistant and silent during rainfall, eliminating one of the most common issues associated with rooftop decks. These performance characteristics reduce long-term maintenance demands and help protect the contractor’s reputation long after handover.

A Rooftop Built to Last

The completed rooftop event space demonstrates what can be achieved when installation challenges are addressed through system-led thinking rather than ad-hoc solutions. By combining a flexible, fire-rated substructure with precision-manufactured decking boards, the project team delivered a deck that meets the highest standards of safety, durability and visual quality.

For contractors, this project reinforces the value of working with systems that are designed for real-world conditions. Wallbarn’s role in supporting the installation process, from early technical guidance to on-site coordination, ensured that a complex rooftop build was delivered on time, to specification and without compromise.

To view the full case study, please click here.